-40%

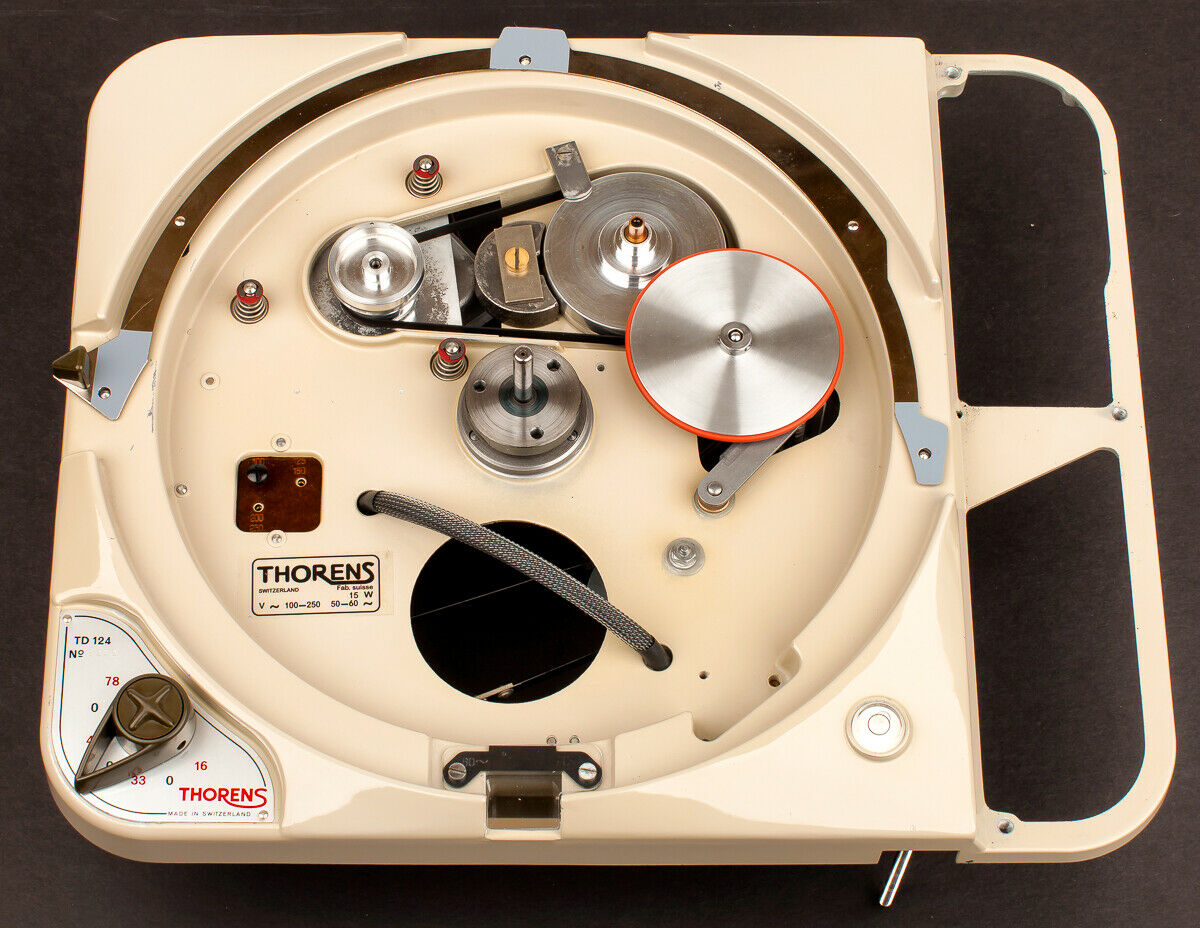

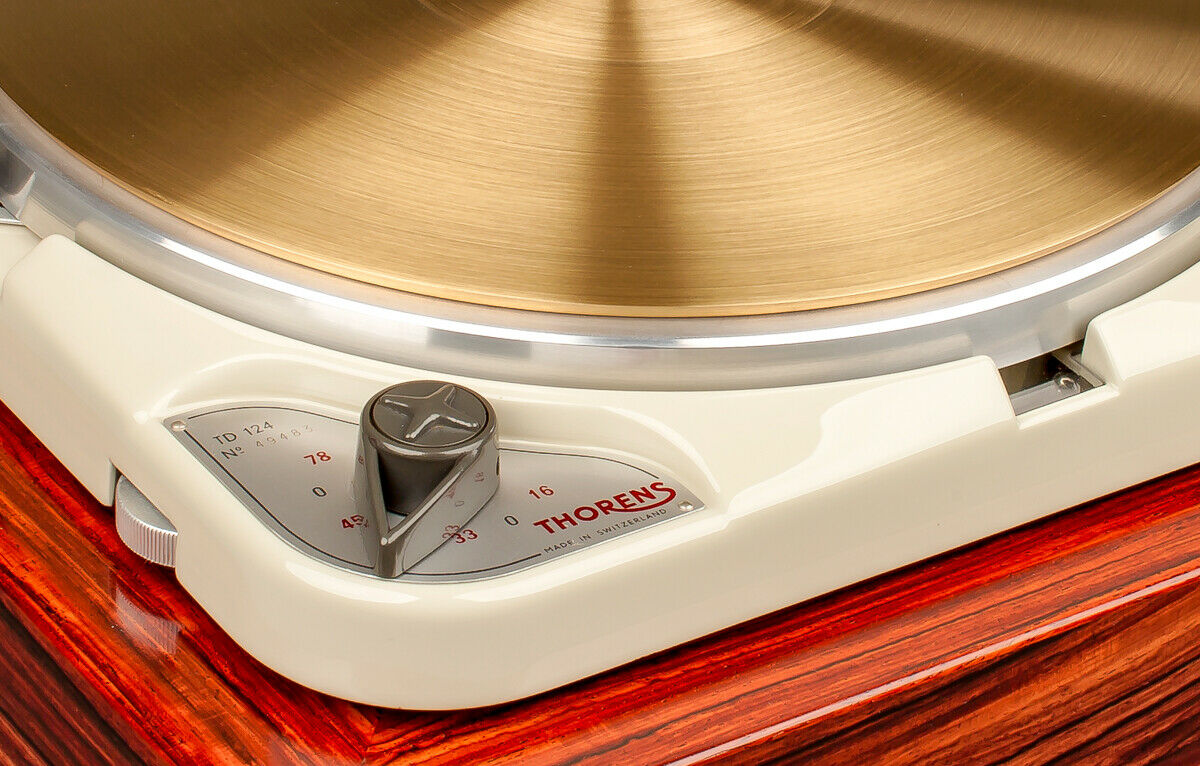

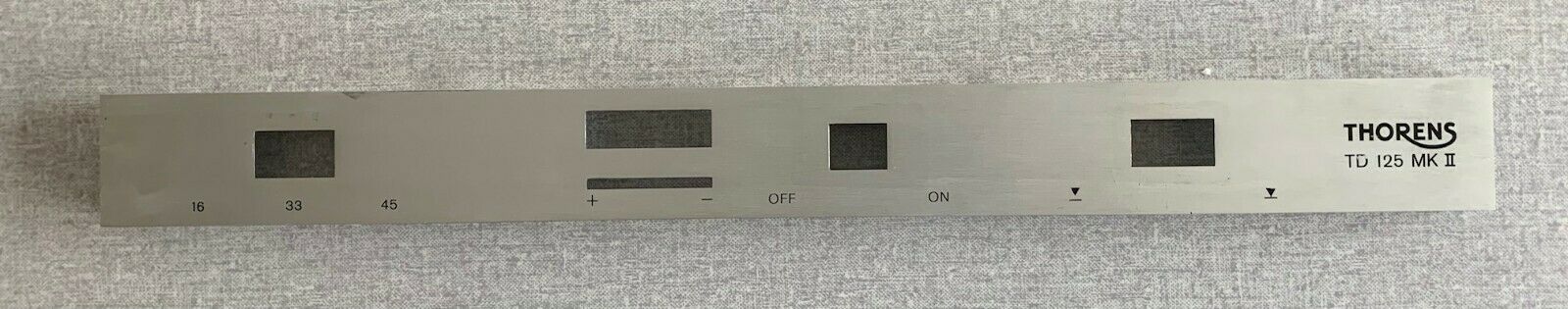

Thorens TD124 Full Restoration, Motor, Bearing Service by Woodsong Audio TD 124

$ 736.56

- Description

- Size Guide

Description

TD124 Restoration and Rebuild ServiceWe are Woodsong Audio, offering the most comprehensive and detailed service and restoration available in the United States, for the Thorens TD124.

We love the TD124, and do whatever is necessary to bring your turntable to it's full potential. This is our art, and our passion.

Our rebuild service is based on a flat rate of 0 for the labor only,

plus the cost of parts used.

In the case where you provide us with any usable parts that you may already have, we will offer a credit to you for your parts.

On the same day that your TD124 arrives in our shop, we unpack it, inspect it, and contact you to confirm safe arrival, and share with you what we see, including any issues.

The TD124 is a superbly engineered turntable, and with cleaning, replacement of worn parts, some careful bearing work and fine tuning, almost all of them can be brought to a level of performance which exceeds original factory spec.

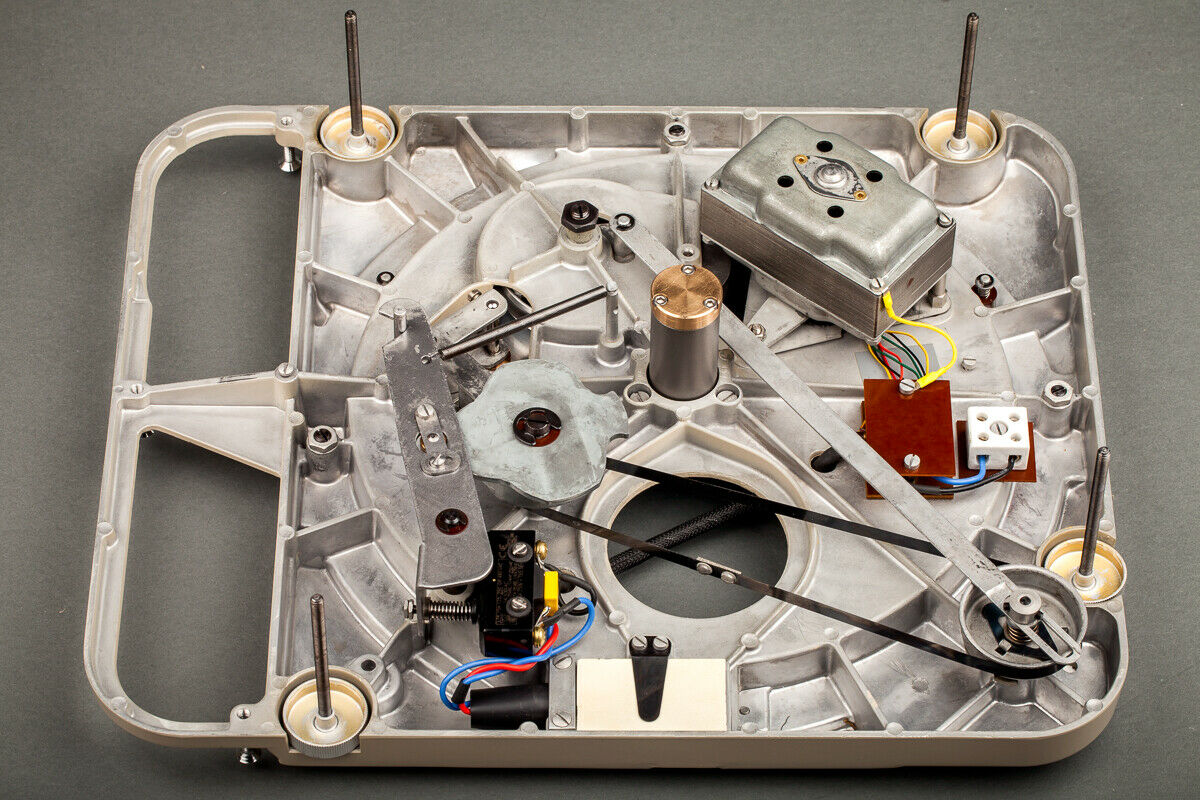

We use a powerful ultrasonic tank for cleaning of linkages, hardware, motor case halves, and other parts, to achieve a level of clean that cannot be reached by other means.

Due to the fact that the original lubricant used by Thorens has hardened in almost every case after all of these years, added to the reality of 50+ years of contaminants in the oil holding structure of the old sintered bushings,

we replace all sintered bronze bushings in your deck, including the main bearing bushings,

motor bushings, and step pulley bushings.

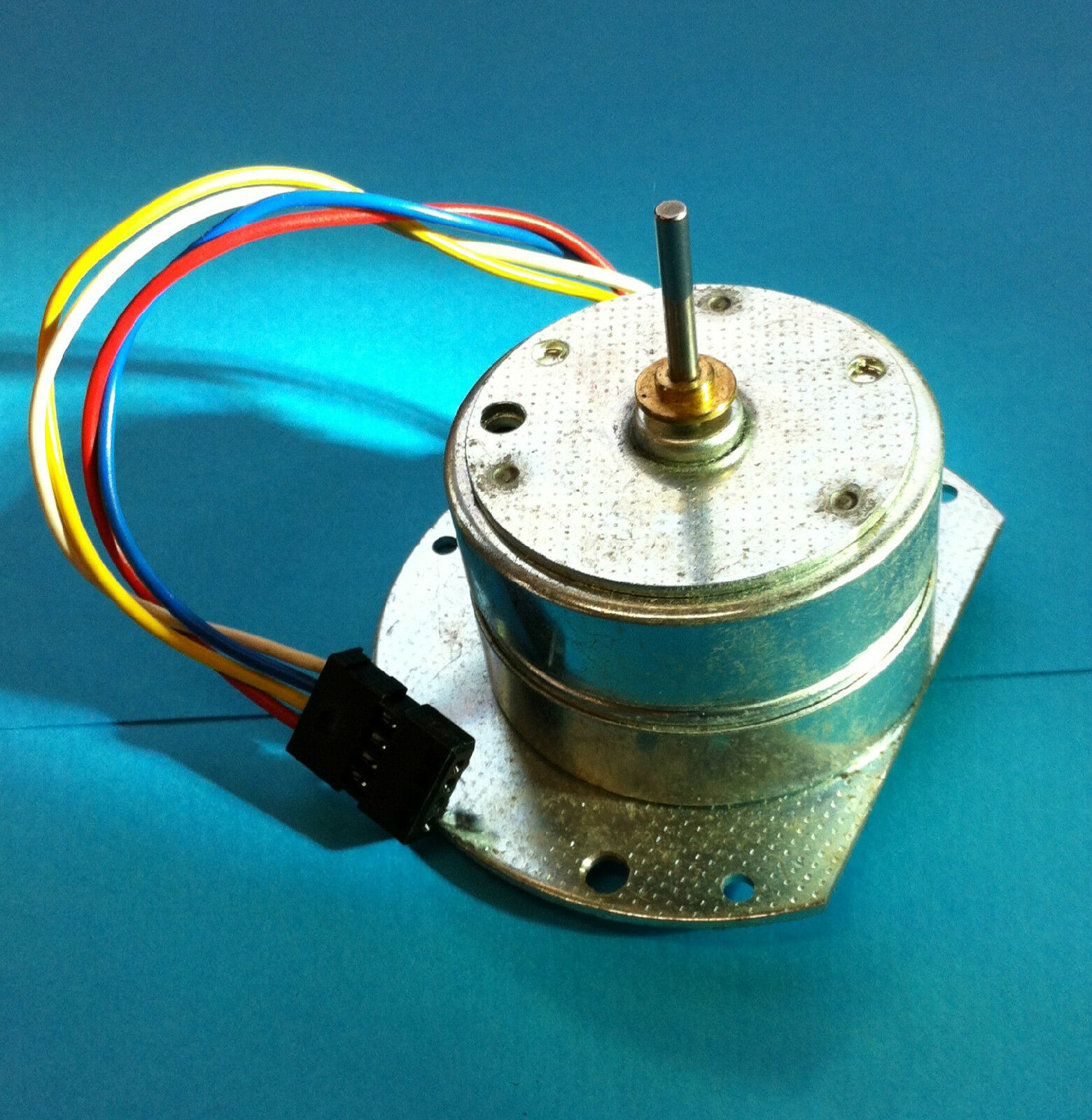

In most cases, the motor bushings are worn beyond the point of reliable long term service, and need to be replaced, regardless.

Worn motor bushings can be made to run, but they will fail prematurely, often causing damage to the motor spindle bearing journals.

For the motor bushings we use the pressed sintered bronze bushings manufactured by AudioSilente.

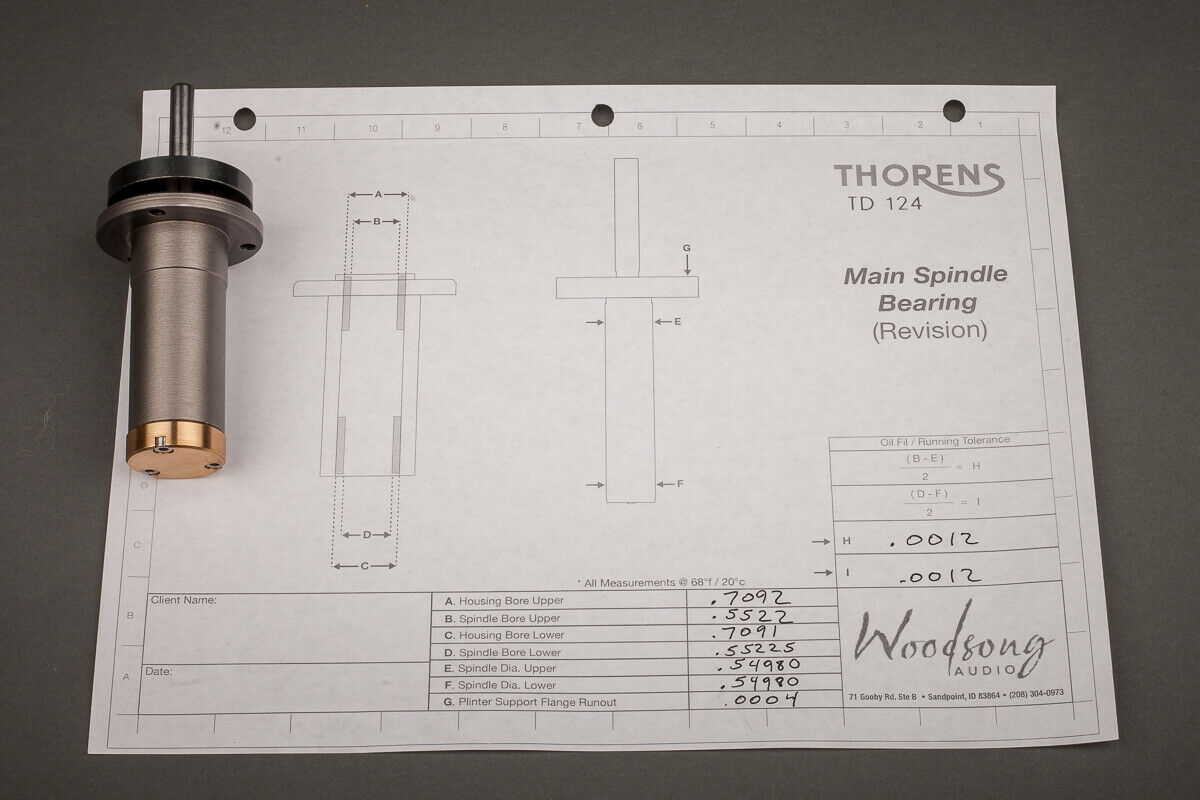

For the main bushings, we use our own precision manufactured ‘ConcentricSized’ bushings.

Precision bearing work is one of our specialties.

See our motor and main bearing service listings for more specific and in depth information. Others offer replacement of these bushings, but almost all lack the precision measuring equipment necessary to ensure proper running tolerances and bushing alignment after install, and the run-in prior to shipping. This is essential to a top performing deck.

Below is what is included in this listing. This is for work for complete restoration work done on your deck, plus the parts listed below. None of the decks in the photos are included, these are for reference only.

·

Specialized full main bearing rebuild and blueprinting, including installation of our own precision made 'Concentricsized' main bushings, our own bronze thrust cap with torlon thrust pad, and sapphire thrust ball assembly, and multi-day run in with numerous oil changes to insure correct operation. Our thrust bearing design is the best available, giving unequaled speed stability, rumble levels below the measurable threshold, longevity, and it does not leak, unlike the original Thorens thrust plate which leaks in almost all cases.

It is a massive improvement over the stock thrust bearing design.

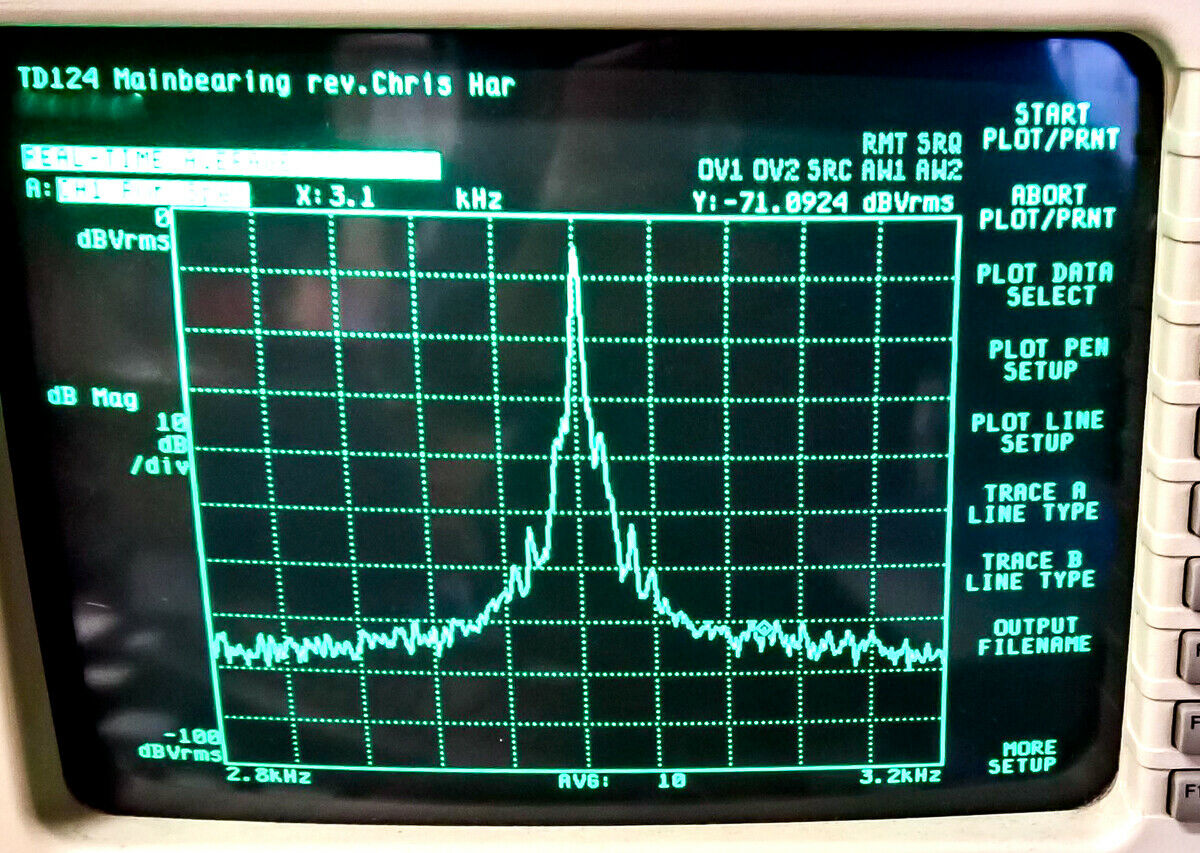

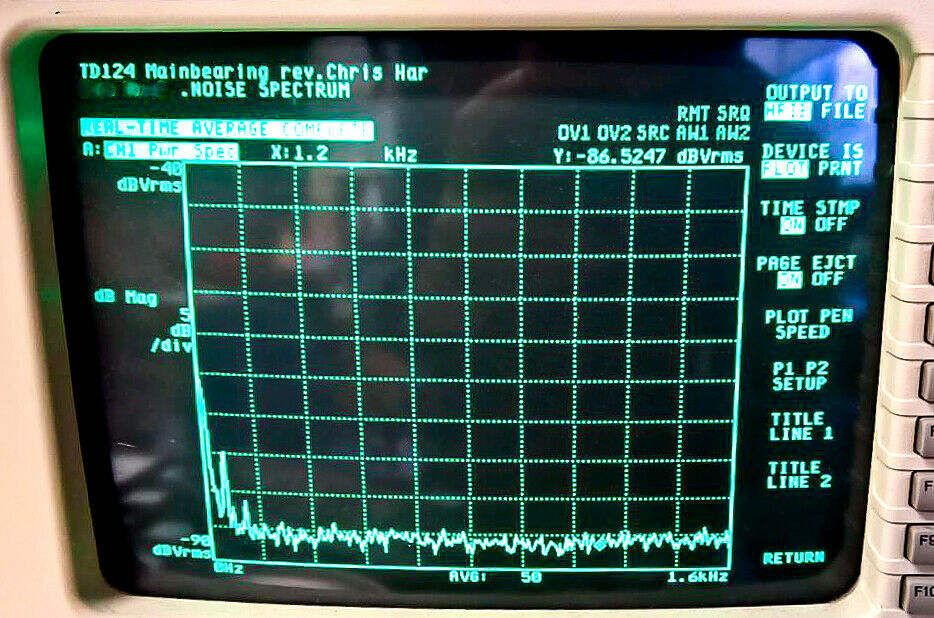

(see the graphs in the photos showing a speed spectrum measurement and the other showing a noise measurement) A properly functioning main bearing is critical to turntable performance and speed accuracy, this is one of the biggest improvements you can give to your TD124. More information on our bearing process can be found on our TD124 bearing service ebay listing. Our bearing work is one of the things that sets us apart from our competition.

·

Motor rebuild including new AudioSilente motor bushings, new torlon thrust pad and new SiN3 motor spindle thrust ball, coils checked for correct impedence, motor spindle journals carefully hand polished, motor case aligned for quiet operation, and multi day run-in and speed check for 1740rpm +/- for 60hz 120v operation.

What others call a ‘super motor’ is what we do as standard.

·

New motor coils available if yours are faulty, at additional cost. Rarely needed, but we stock them just in case.

·

Mk1 to MK2 motor suspension studs installed.

For MK2 motors, a credit is issued for this.

The Hanze Hi-Fi spring motor suspension is installed. This is a huge improvement over the stock rubber bushings or aftermarket polymeric motor suspension bushings used by others. This is a necessity in our opinion, one of the single best improvements you can make to your TD124. There is no comparison.

·

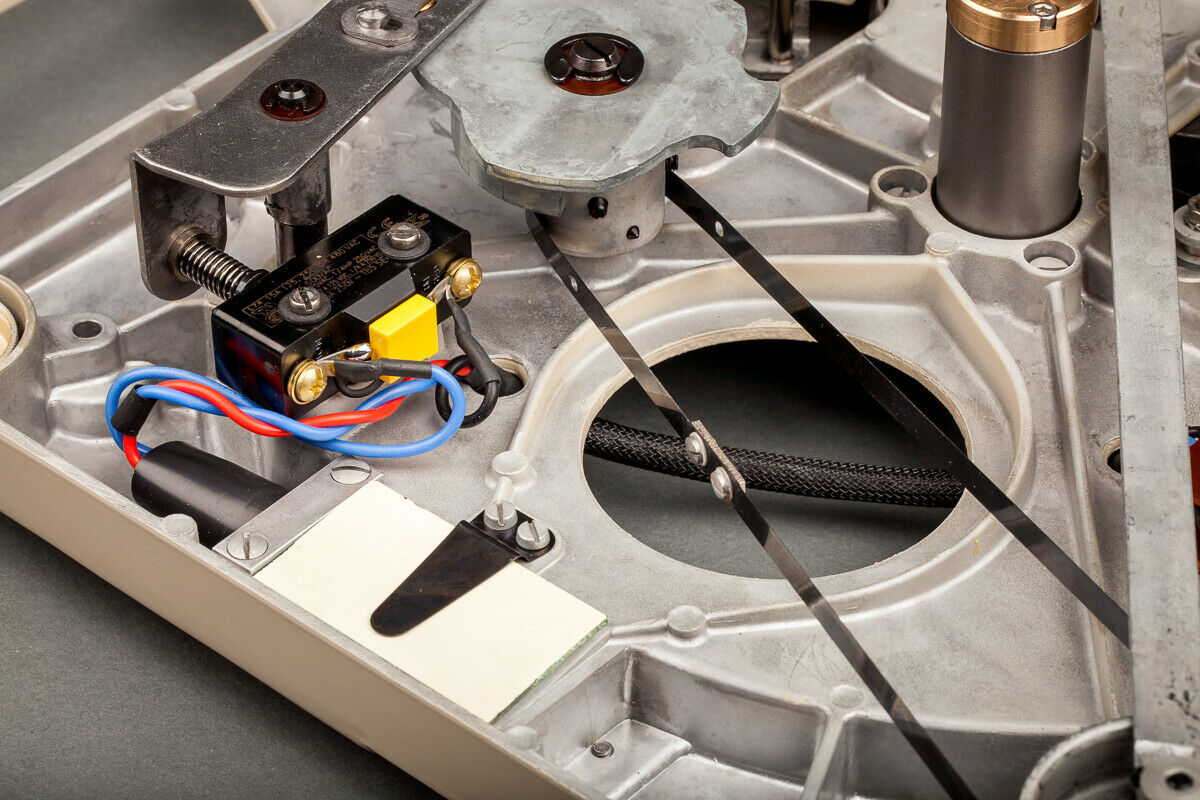

Ultrasonic cleaning of all linkages, hardware, motor case halves, and other parts.

·

New silicon jacketed wiring harness installed

·

New NOS OEM strobe resistor

·

New micro-switch and X2 rated spark suppression capacitor installed. (there is no 'start capacitor' on the TD124, only a spark suppression capacitor)

·

New sintered bronze step pulley bushings installed

·

New step pulley thrust pad installed, and step pulley bore sealed against oil leakage

·

Drive pulley and step pulley cleaned and polished

·

New Hanze Hi-Fi low noise drive belt

·

New AudioSilente idler wheel with our proprietary ultra-quiet O-ring. New Teflon idler wheel thrust washer installed.

·

Chassis is cleaned and polished.

(Top quality refinishing is available on request)

·

New neon strobe bulb

·

New Thorens label

·

Careful adjustment and lubrication of all linkages for correct and quiet operation

·

Eddy brake adjusted for correct speed at middle of adjustment range.

·

Upper platter clutch height adjusted for correct operation

·

Upper platter flattened if possible.

We can usually improve warped platters.

New Retrotone upper platter available on request at additional charge. Upper platter is polished on a large buffing jack (we do not deep clean mats, as we believe that the best performance from a TD124 is with the use of a new mat. We do not use the old mats in our own system)

·

Woodsong Audio upper platter mat adapter installed into upper platter.

·

Unit is fully run tested over the course of several days to confirm exceptional operation

Turnaround time is approximately 2 weeks.

We are easy to find on the internet, and are happy to speak on the phone about exactly what we will be doing to your turntable, and why, and also to answer any questions you may have. We are also happy to discuss how to purchase a used TD124, or anything else related.

Your TD124 will be return shipped in new, application specific boxes.

If you want the best service available for your TD124,

we guarantee it. You will hear the difference in quietness, and in the sheer presence of the music that can only come with properly fitted bearings all around, and a finely tuned deck.

International service is available, even though it is not shown in this listing.

Please contact us prior to purchase so we can make this available to you.

We offer absolute top level custom chassis refinishing, and for decks that have linkages that are looking tattered and need some protection, we offer re-plating service from a local precious metals lab in the same metal as the linkages were originally plated in.

Please contact us for details about either service.

Thank you for looking.

Chris

Woodsong Audio